HOUSTON, March 24, 2022 – Reliable Industrial Group (RIG) and Hydrocarbon Filtration have joined forces to expand the current platform of industrial reliability and pre-commission services with the addition of oil filtration systems & dehydration units.

The addition of Hydrocarbon Filtration allows RIG to expand services with a fleet of rental equipment along with proven capabilities to manufacture high-quality industrial filtration systems, dehydration units, and other equipment for RIG’s growing customer base. “In partnership with RIG, ExxonMobil provides industrial operators with an end-to-end solution for a range of maintenance services across a plant’s entire lifecycle,” said Aileen Wang, North America Field Engineering Services Manager, ExxonMobil. “We look forward to providing even more value to our operators by incorporating Hydrocarbon’s best-in-class filtration services into our already robust Mobil Servsm Integrated Lubrication Services offer.”

RIG’s strategy remains focused on bringing proven processes, engineering, training, and technology to expand market share and deliver reliable services and equipment to customers.

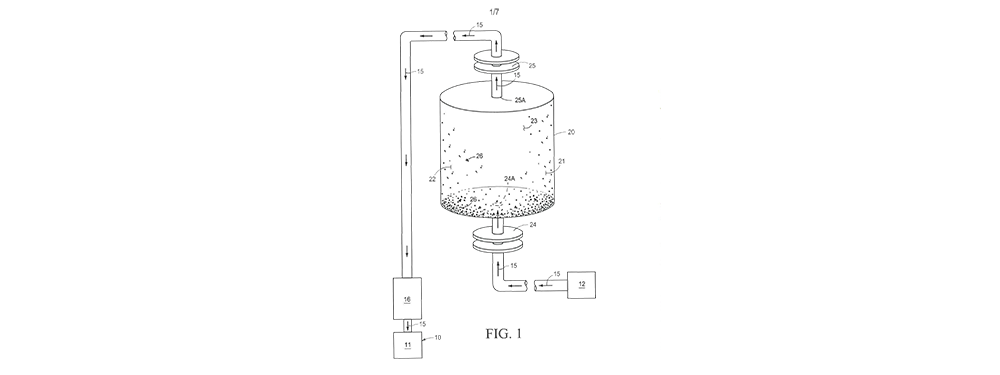

Hydrocarbon Filtration designs and manufactures the latest in cutting edge oil filtration systems, vacuum dehydration units, varnish absorption systems, and hydraulic oil reclamation equipment. They specialize in the filtration, cleaning, and reclamation of hydrocarbon based fluids such as turbine lube oil, hydraulic oil, engine oil, gear oil, light & heavy fuel oils, fire retardant hydraulic fluids, dielectric – transformer fluids, heat transfer fluids, gasoline, solvents and many fluid chemicals.

Hydrocarbon Filtration also removes light hydrocarbons from water for water polishing applications. They offer a wide variety of oil filtration systems and purification systems to solve a multitude of contamination issues ranging from, particulate, water, dissolved solvents – gasses, varnish and acid or pH reduction. In addition, they specialize in technologies including vacuum purification, dehydration and distillation; electrostatic – ion exchange; coalescing & cohesive bonding; absorption & adsorption; and direct particle interception and capture.

Duke Cooper, President and Owner of Hydrocarbon Filtration, is recognized as an industry thought leader with over 30 years of experience designing, engineering and manufacturing industrial oil filtration systems. “RIG has been a valued customer of Hydrocarbon Filtration for years. We have always been closely aligned. This will allow both companies to meet growing market demand. With an increased rental fleet of equipment and RIG’s inventory of specialty fittings, equipment and national footprint we can serve customers with full turnkey services and rental of equipment and fittings to meet our clients’ needs on critical path projects,” said Duke Cooper.

“We are happy to have Duke and his team join our platform of companies because this continues to put our customers first by providing industry leading filtration equipment with experienced service and engineering to meet the growing market demand. Mr. Cooper will remain with Hydrocarbon Filtration and his team will is a valued part of our growth,” said Jason Bandy, President Reliable Industrial Group.

About Reliable Industrial Group (RIG)

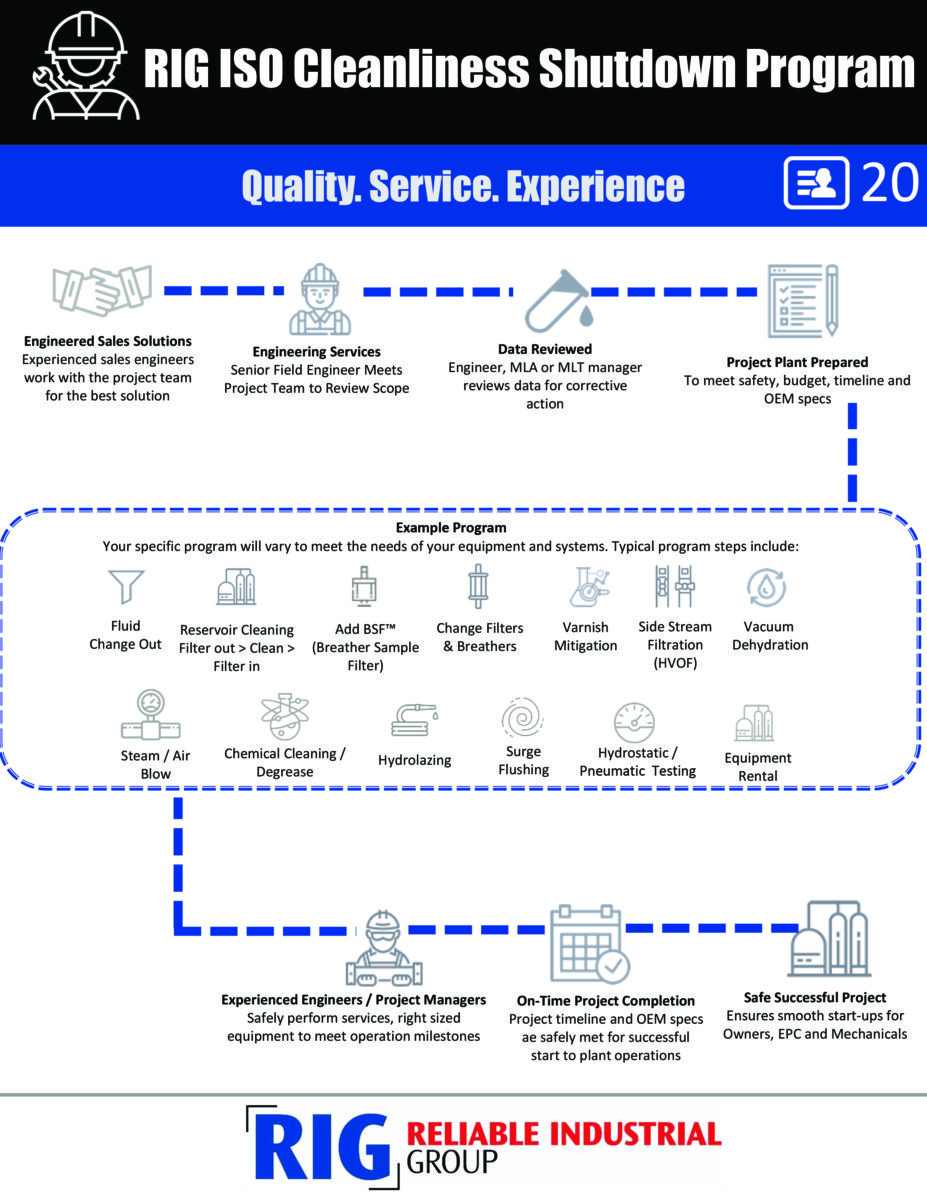

Reliable Industrial Group (RIG) (www.therigteam.com) has locations throughout the U.S. and Canada, with primary service operation in Houston, Texas. RIG performs technically advanced, highly specialized industrial pre-commission cleaning, oil flushing, chemical cleaning, varnish mitigation, steam and air blows, hydrolazing and other emergency, pre and post operational decontamination services to guarantee system cleanliness on critical turbine, compressor and hydraulic systems in North America. The company was founded in 1989 and is experiencing consistent growth by providing the market with technically trained operators and engineers. For more information please contact [email protected].