- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

Six Ways To Verify Oil Flushing Success

It can be daunting to try to verify the results of an oil flush. Particles as small as 2 microns can damage your equipment, but the human eye strains to see particles 30-40 microns in width. Besides super human eyesight or giant coke bottle glasses, we have six reliable ways you can personally verify your lube oil cleanliness. You should always use two types of verification; particle counts for microscopic contaminates and inspection media for particles visible to the naked eye.

1. Visual Inspection – While superhuman eyesight is required to see some particles, it is still a good idea to do a visual check. Using a 100-mesh screen (normally required by manufacturers), you can make sure nothing obvious is still running through your system.

2. Patch Kits – For quick checks and people who are okay with knowing they are in the ballpark instead of having a specific and reliable measurement, patch kits offer a fairly reliable and quick solution. Because they do leave room for human error, we recommend always backing up this method with laboratory testing (which can take longer).

3. Independent Lab Analysis – lab results are the most accurate way to know what precisely is happening with your lube oil. We work with an independent lab that returns results in 24 hours or less, but some analysis and labs can take longer. A patch kit for instant verification plus a sample sent off to the lab is always a way to have quick results now and peace of mind later with the certified lab results.

4. Portable Particle Counters – These are fast, reliable and great at identifying microscopic particles. You’ll want a unit that provides ISO and NAS cleanliness code counts. This is still a DYI solution, and false results can easily occur if the wrong type of particle counter is used for your application or you don’t check the calibration before each analysis. Our basic guide for selecting these is:

- Light-refracting units – best for turbine and hydraulic fluids, these can give incorrect readings with dark oils and moisture contamination.

- Pore-blockage – use for darker oils and moisture; these can be sensitive and taking your time setting them up and calibrating them is important.

5.Strainers & Filters – strainers and filters offer tried and true ways to monitor your system for most particles but may miss microscopic contaminates. There are several choices when it comes to strainers, including:

- Wye Strainers – Common, inexpensive, and easy to change, but easily crushed, They can also give a false positive if contamination drops out in to the screen cover.

- Basket Strainers – Used commonly in modern flushing, but can be scarce and expensive because there are not standardized baskets and housings. However, they accept full flow and have a sealed bottom to capture all particles.

- Witch’s Hat Strainers – Not commonly used by flushing professionals, but some manufacturers do require this strainer at the return header to prevent reservoir contamination. These must be checked often since they are prone to blowouts and tears.

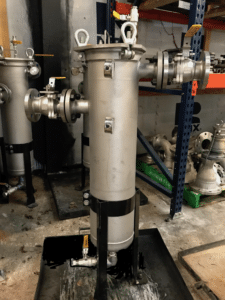

- Bag Filters – Common and inexpensive, these filers are available in many micron sizes and distributed globally. The drawbacks to bag filters are the potentially expensive housings, the difficulty in inspecting them, and the fact that they do let many contaminates pass through.

5. Flange Screens (a.k.a. Slip Screens) – These are preferred by oil flush technicians, due to their ease of placement between flanges in gaskets with no disturbance to the piping or machinery. These screens are easily cleaned and reused repeatedly, especially during a flush. The drawback to slip screens is they can become clogged and back up fluid upstream or be destroyed.

Learn More About our PLI-Screens here.

Source: Larry B. Jordan