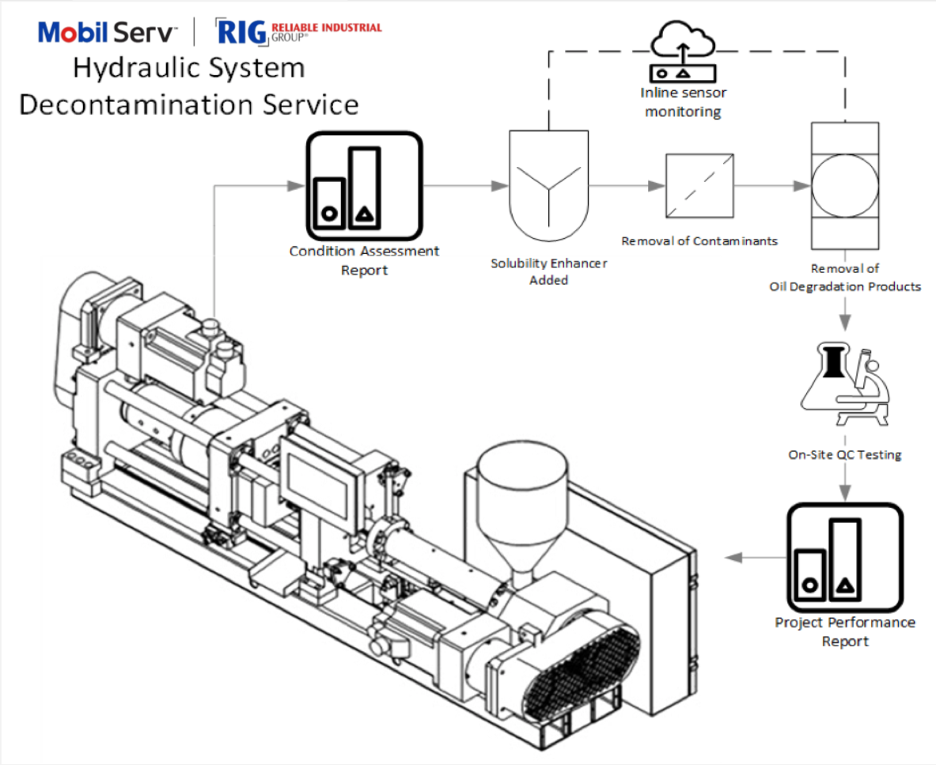

Hydraulic System Decontamination

Mobil and RIG have teamed up through the MobilServ program to provide the optimum contamination control and varnish mitigation service for critical hydraulic systems. Using state-of-the-art chemistries and purposely-build filtration skids, the service provides restoration of your oil’s performance and cleaning of the lube oil circuit, without shutting down your machine.

Benefits

- Immediate relief from the negative consequences of oil degradation and varnish

- Cleaning of machine internals and lube oil system with no downtime required

- Long-term protection from varnish-formation

- Reduced waste through oil life extension

- Improve production yield and decreased scrap rates

- Lower maintenance costs

In situ refortification of the hydraulic oil’s additive system allowing the life of the oil to be extended with enhanced performance

800-770-4510 (Domestic)

+1 281-339-5751 (International)

How it Works

Our proprietary turnkey service shows up at your plant, with all of the technology to allow immediate cleaning of your hydraulic oil systems without requiring machine shutdown.

What It Solves:

Varnish is an oil-derived deposit and a common problem in hydraulic systems. It produces a sticky, tenacious residue that plays havoc on the reliable performance of the hydraulic system. Varnish can cause valves to stick, risking the control of the system. It acts as an insulator, preventing the oil from performing its cooling function, resulting in hotter, less efficient systems. Varnish can foul filters, requiring frequent changes. These deposits may also accumulate, plugging up oil lines or heat exchangers.

Husky Lima OH – New Hydro Plant- The RIG team performed chemical cleaning on the reformer, air blowing of the process lines and continuous steam blows of the header and users.

DTE Cogeneration to Solvay Marietta, Ohio. RIG performed chemical cleaning of the boilers, gas line air blows and steam blows.

Valero Cogen Wilmington CA – RIG performed citric acid chemical cleaning of the HRSG, gas line air blow to the duct burners and combustion turbine. Oil flushing of the combustion turbine and Kobelco compressor. Steam blows to the header.

Typical Air Blowing Procedure

Our team of engineers will help to develop a custom procedure for your situation. Typically, an air blow project progresses as follows:

- Systems to be cleaned are identified on the P&IDs and cleaning paths are marked. Injection points, exits points, valve positions, and equipment to be removed are detailed on the drawings.

- Cleaning force ratios, air pressures, and cleaning velocities are calculated for each of the air blows.

- Connection point details are recorded, and a bill of materials of temporary adaptors and equipment is created.

- The air blowing equipment including air compressors, air dryers, silencers, hoses, and temporary connection fittings is shipped to site.

- In the field the RIG Supervisor will walk down the system to be air blown following the procedure prepared by the engineer. Connection points, items to be removed, and access to the piping will be noted.

- The RIG crew will verify that the piping system is isolated. The temporary air blowing equipment will then be connected to the system.

- A safety briefing will be held and workers in the area will be notified that air blowing activities are about to start.

- The RIG crew will then pressurize the piping systems and release the air at the exit point. Contamination levels will be noted and the relevant parties (RIG, client, owner) will witness the cleaning.

- If targets are required, they will be inserted into the exit piping via a target inserter.

- Once the system is accepted as clean the temporary equipment will be removed from the piping and the system will be reinstated to await startup.

What is air blowing?

Air blowing is an industrial plant service that uses dry oil-free compressed air to clean piping of debris and contaminants. It will remove construction debris, liquids, and semi adherent material, and safely transport the removed items out of the system. This method allows for quick cleaning of piping systems without the need for disposal of large volumes of liquid cleaning solutions.

Should I hydrolaze before air blowing?

Hydrolazing, sometimes also called aqualazing or hydromilling, is a pipe cleaning service that can significantly enhance the results of steam and air blowing. This high-pressure water jetting process is effective at removing mill scale, construction debris, and process deposits. Air blowing will not remove all mill scale from the internal pipe wall. For systems that require a high degree of cleanliness the combination of hydrolazing followed by air blowing can yield excellent results without the generation of large volumes of chemical cleaning waste.

When should I use air blowing vs. steam blowing?

Air blowing works well in combination with chemical cleaning. The air blows will remove all loose debris. The chemical cleaning solution will then dissolve the remaining mill scale. Air blowing puts less direct stress on your system than steam blowing does, so if a chemical clean will remove the contaminants, it is easier on your system to combine it with air blowing.