Updates

Visit with Mobil Serv | RIG at the 7F Users Group Conference

We are excited to be attending the GE 7F Users Group Conference from May 23-27, 2022 at the Fairmont Dallas Hotel. The RIG team will be onsite Tuesday in Booth T-51 – see the Floor Plan here. In addition, ExxonMobil will be presenting on at 11:00am on Tuesday, May 24th. The presentation “Mobil Solvancer: Improving […]

Come See RIG at POWERGEN International & Distributech 2022

Reliable Industrial Group will be attending POWERGEN International & DISTRIBUTECH International May 23-25th in Dallas, Texas. Come see us in Booth:4516 for our umbrella company, Blue Wolf Performance Solutions. We are excited to be a part of these events and see some of our power generation & electric distribution customers in person, meet new people in […]

Blue Wolf Performance Solutions Acquires Reliable Industrial Group (RIG)

Blue Wolf Performance Solutions ("Blue Wolf"), a national industrial cleaning and maintenance services provider, announced that it has acquired Reliable Industrial Group ("RIG"), a company that specializes in plant maintenance and pre-commissioning services based in Houston, TX. The acquisition announcement was made by Tim Hennigan, CEO of Blue Wolf: "We are very excited to welcome RIG to [...]

Hydrocarbon Filtration & Fleet of Oil Filtration Systems Joins RIG

HOUSTON, March 24, 2022 – Reliable Industrial Group (RIG) and Hydrocarbon Filtration have joined forces to expand the current platform of industrial reliability and pre-commission services with the addition of oil filtration systems & dehydration units. The addition of Hydrocarbon Filtration allows RIG to expand services with a fleet of rental equipment along with proven capabilities to manufacture […]

Elden Consulting & Industrial Chemical Cleaning Services Joins Reliable Industrial Group (RIG)

HOUSTON, Texas – Industrial chemical cleaning and lube oil flushing company Elden Consultants & Industrial Services has joined Reliable Industrial Group (RIG) enhancing RIG’s service offering with Elden’s in-house experts. With over twenty years of industrial system cleaning and commissioning services, Elden’s team brings efficient processes and a unique methodology developed over decades of experience. […]

Mine Shovel Inspections Save Millions in Repairs and Provide Other Benefits

Did you know that through our partnership with Exxon Mobil Serv program we provide mining shovel inspections? An on-site technician performs regular inspections and provides insights that will optimize performance and improve equipment life. In working with one customer over the past year, many recommendations and simple repairs have been made including replacement of failed […]

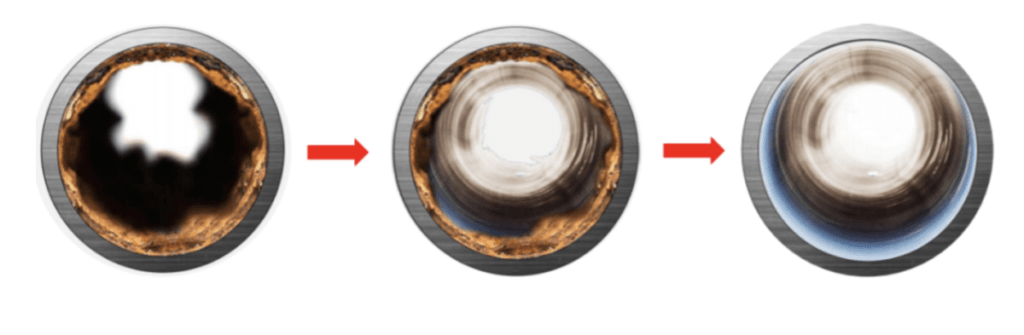

New Mobil Solvancer Product Makes Removing Varnish a Breeze

Exxon Mobil has announced the introduction of Mobil Solvancer to the North American market. This product builds on Fluitec’s DECON technology to make removing varnish and other organic deposits much easier. This is an oil-soluble cleaner designed for: Gas and steam turbine applications Compressors Hydraulic systems It can be added to in-service oils to quickly […]

Hydraulic System Decontamination Service for Plastic Injection Molding Manufacturers

Mobil and RIG have teamed up through the MobilServ program to provide the optimum contamination control and varnish mitigation service for critical hydraulic systems. Using state-of-the-art chemistries and purposely-build filtration skids, the service provides restoration of your oil’s performance and cleaning of the lube oil circuit, without shutting down your machine. How It Works: Our […]

Get Major Efficiency Gains with Newly Announced Mobil SHC 918 EE Turbine Oil

Are you running a GE Frame 9H, 7HA, 7FA or 6FA? Did you know that you can increase your turbine bearing efficiency by 15% by switching to the Mobil SHC 918 EE Turbine Oil? Developed together with GE and Mobil, Mobil’s SHC 918 EE is the first product to meet GE’s rigorous energy efficient turbine […]

Significantly Reduce Required Man Hours for Vessel Cleaning with New Patented Process

Using our new 360 TotalScrub Tank Cleaning Systems, you could see a savings of 24-36 hours of cleaning time per vessel. RIG’s Tank TotalScrub System sprays oil in a 360 rotation, allowing the run-down tank interior to be simultaneously “washed” with the flushing oil. This technology allows for: Savings of 24-36 hours of cleaning time […]

Why You Can’t Skip Preventative Maintenance with Condition Based Monitering

How long has it been since you serviced your lube oil system? With todays technology for oil analysis we have gone to a conditioned based response. Condition based is great for monitoring current condition of lubrication in the system but many times at the cost of preventative maintenance of the lube oil reservoir and filters. […]

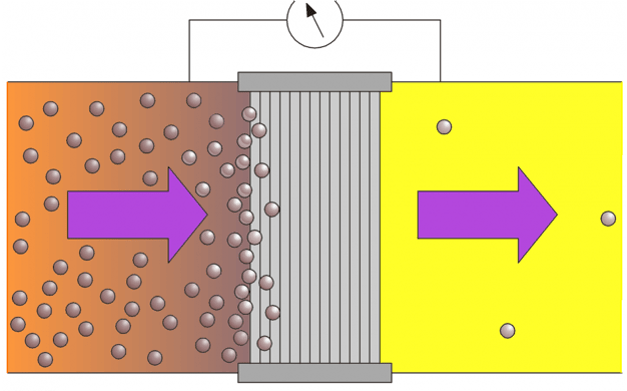

What filter do you need?

Generally speaking, there are 3 types of filters for solid and soft contamination. Each application is dependent on the efficiency and performance needed. Synthetic Microglass filters have smaller pore sizes with a higher efficiency ratio than most other filters. Synthetic media is less sensitive to moisture than cellulose or blown media and has a higher […]

Power Plant Saves $5 Million with Preventative Maintenance

A peak power plant experienced multiple unit trips and fails-to-start. These were caused by electrohydraulic control (EHC) servo valve failure. The valves were being affected by several contaminants including water, acid, particulate, gels and dissolved metals, coupled with low resistivity. Keeping fluids clear of contaminants is crucial to the operational readiness of power plants. Fail-to-start or […]

ExxonMobil Expands Mobil Serv℠ Program with Reliable Industrial Group

Mobil Serv has expanded its integrated lubrication services program to be an end-to-end solution for all plant commissioning, reliability and integrated service needs ExxonMobil and Reliable Industrial Group engineers will work with customers to deliver a full range of services including machine performance insights and on-site support SPRING, Texas – ExxonMobil announced today it will [...]

Optimizing Maintenance of Gas Processing Facilities

Regular maintenance and lubricant reconditioning of critical gas processing equipment can extend the life of your critical components, reduce oil replacement costs, and prevent the major causes of equipment failure. Which services should you be performing and how often? The chart below lays out an optimal maintenance schedule for Gas Processing Plants. Use this as […]

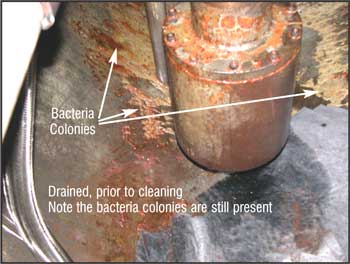

Preventing Bacterial Growth in Your Turbine

Bacteria colonies are a growing and expensive problem As steam turbines throughout the United States age and maintenance intervals are pushed out, preventing bacteria growth inside turbines is becoming ever more important. Bacteria colonies can affect oil quality, produce corrosive by products, and clog control systems which can result in significant repair costs. There are […]

What Oil Flush Should I Use?

Knowing the difference between oil flushes, when to use which, and the proper terminology to describe them is key to extending your equipment life. While our certified field technicians are exceptional at making sure the right flush is applied every time, it is important to us that our customers understand what is happening with their […]

What is Pre-Commissioning and What Does it Include?

Pre-commissioning is a critical project phase that takes place following the construction of piping and process systems, but before those process products are introduced into the systems. The purpose of pre-commissioning is to safeguard the integrity of your systems and ensure they don’t have debris or contaminants that can damage equipment and delay system startup. […]

How Set Your Target ISO Cleanliness Codes

ISO cleanliness codes help us understand the amounts and sizes of contaminating particles in fluids and set target goals when cleaning fluids. ISO codes quantify contamination levels per milliliter of fluid at three distinct particle sizes: 4µ, 6µ, , and 14µ. When you are looking at an ISO code, you are looking at three measurements; [...]

The Complete Field Guide to Lubricant Maintenance & Troubleshooting

The more contaminates floating around your fluids, the more wear and tear your systems and equipment take. To know whether you are putting machines at risk, you have to know what contaminate levels are safe. Use this guide to learn how to: Correctly identify, analyze and improve lube oil contamination problems Interpret and set ISO code targets [...]

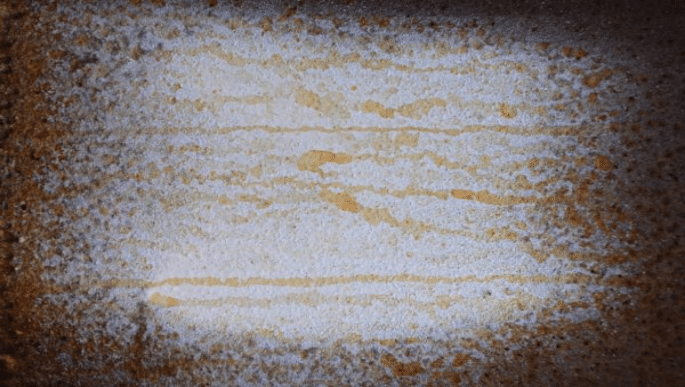

Varnish Removal

What Is Varnish? Before we discuss how to remove varnish buildup, it is important to understand what it is and how it occurs. As oil is heated and cooled under normal operations, oxidation in lubricants and additives creates organic by-products. This results in the formation of soft, sticky, polar insoluble particles floating in the oil […]

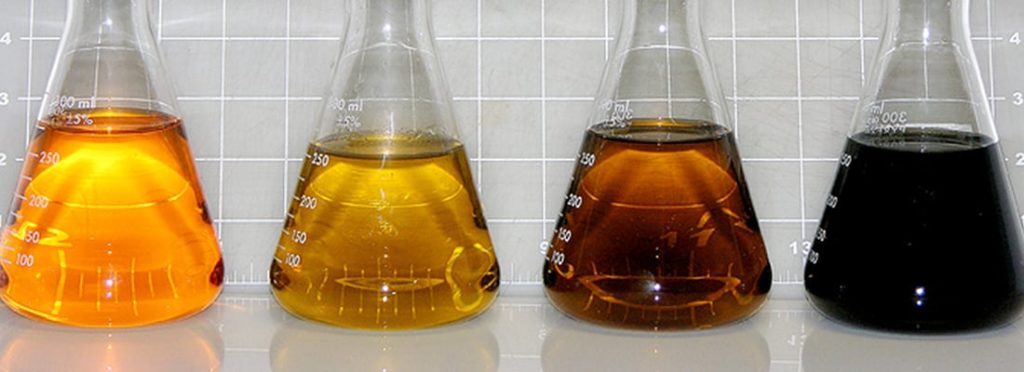

Is Your Hydraulic Fluid Getting Darker? Here’s What To Do

Hydraulic fluid is the lifeblood of your system, keeping everything lubricated and ensuring smooth machinery operation. It’s critical to regularly test your fluid to ensure contaminate levels are below ISO cleanliness levels and lubricant is circulating properly throughout your system. Unmonitored changes to your fluid could produce harmful effects that impact your system performance. But […]

New Technologies Drive Better Cleaning Procedures

Pre-cleaning and regular maintenance of piping, critical system components, and lube oil systems are critical to extending the life of equipment and ensuring safe operations. But every minute we spend cleaning means our plants are not operational. Fortunately, innovations in the pre-commissioning and preventive maintenance industries are helping speed cleaning processes up while improving equipment longevity. Some […]

When To Use Steam Blowing vs. Air Blowing

When and why to use steam vs. air blowing is not always easy to tell. Both are good methods and have their use cases. Generally, air blowing is a less stressful method of cleaning than steam blowing, but it doesn’t do quite as thorough a job. Usually, the level of contamination and your target ISO […]

How To Reduce Noise and High Temperatures During Steam Blowing

Steam blowing is critical if you want to ensure piping, boilers, and gas turbines are not contaminated with mill scale, debris and grease before full operation. With proper steam blows, you can protect your turbines and plant equipment from damage upon startup or operation, potentially saving millions in repairs and unplanned downtime. This procedure forces […]

Six Ways To Verify Oil Flushing Success

It can be daunting to try to verify the results of an oil flush. Particles as small as 2 microns can damage your equipment, but the human eye strains to see particles 30-40 microns in width. Besides super human eyesight or giant coke bottle glasses, we have six reliable ways you can personally verify your […]

Pre-Commissioning: The most critical step

The most delicate moment in a plant project is between fabrication/construction and plant startup. Process systems and other critical equipment must be moved, installed, hooked up to utilities and set up correctly for a smooth startup. But surprisingly, it’s not problems in any of those areas that often cause bad or even failed starts. Poor […]

How to Choose a Plant Maintenance Contractor

It can be hard to tell which plant maintenance contractors are a good fit for your needs and trustworthy to hire. Online reviews, websites and experience can be fabricated in a few quick keystrokes, so understanding who you are inviting into your facility can be tricky. Here are a few key actions you can take […]

Why You Should Be Hydrolazing Before Steam & Air Blows

Hydrolazing, sometimes also called Aqualazing, is a newer turnaround service that can drastically enhance the results of steam and air blowing. This high pressure water jetting method is effective at removing mill scale, construction debris, and process deposits. Benefits of hydrolazing include: Reduces the cleaning times and costs of steam and air blowing services by […]

High Differential Pressure Doesn’t Always Mean A Plugged Filter

A high differential might not mean your filters are plugged. If you keep replacing filters and are still experiencing the same problem, or if your filters do not look clogged when you pull them, it’s time to consider some other data. Changes in fluid viscosity and excessive filter replacements can give false end-of-filter life warnings when […]

PetrolinkUSA and Cogen Cleaning Technology Join to Form Reliable Industrial Group

HOUSTON, Texas – (Business Wire) October 30th, 2018 - PetrolinkUSA and Cogen Cleaning Technology have joined forces to expand the current platform of industrial reliability and global pre-commission services. The new name of the holding company for the two brands is Reliable Industrial Group (http://www.therigteam.com). Bringing together PetrolinkUSA and Cogen Cleaning Technology will expand the [...]

Developing the Right Oil Flushing Plan

What is the right acceptance criteria to use for oil flushing activities? For clients, new to the world of oil cleanliness and flushing it is easy to get confused by the nomenclature. Those more seasoned professionals will throw out abbreviated words, acronyms, or API (American Petroleum Institute) Standards; like everyone has read and memorized all […]

Why You Need a Quality Filtration Program

How many different lubricants are used throughout your plant? What does your OEM manual recommend for each piece of machinery within your plant? Which bottle of lube oil is oldest? What is the date of the last oil top-off for each piece of equipment? What about the last oil analysis? If you cannot easily pull […]

Why Temporary Filtration is Crucial for Process Equipment

Temporary filtration of hydraulic and lube oil systems is an efficient, cost-effective way to prevent problems before they happen. Often overlooked and underestimated, temporary filtration provides key benefits to the oil and gas industry. These include: Stopping materials from contaminating a system before they can cause damage, downtime, or failure Preventing premature equipment failure caused by plugged […]

Why and How to Test New Oil Deliveries

Have you ever gotten milk from the grocery and later opened it only to find it had already gone bad? Bought a carton of eggs and found a couple were cracked? These things happen. Even if 99.999 percent of the time everything is perfect, that .001 percent can pose a big risk to your health. […]

Our RIG Leadership Mindset

At RIG, we take pride in condition monitoring and predictive maintenance done the right way. We apply hard work, intentional thought, integrity, and transparency every day to deliver the quality service our clients rely on. To consistently meet that standard day in and day out, it takes a world-class team. And it takes a leadership approach [...]

Is Self Performing Flushes Costing You?

Self-Performing vs Flushing Contractor Cost savings on hourly rates of internal labor vs. contract personnel is only a small portion of the flushing expense. There are many factors to take into account that are not quantified in the hourly rate. Most specifically is time. The total hours which can be impacted by flushing a unit […]

Foreign Material Exclusion

What is Foreign Material? To put it in a simply, Foreign Material is any material that does not belong. For this discussion, we are going to focus on industrial lubricants and service contractors. Common Foreign Materials in this category can include anything from: Particulates Comingled lubricants Lint / fibers Moisture Where does foreign material come […]

RIG Emphasis on Pre-Commissioning Safety

At RIG, pre-commissioning safety is paramount, and we have put measures in place to reduce the risk of injury and damage to personnel and equipment. Safety is important to us because it protects our crew (whom we like, or else we wouldn’t employ them) and it protects you from liability and risk. Our crew takes [...]

The #1 Thing Most EPC’s Forget that Will Cost You Later

Did you remember to plan access points for pre-commissioning and cleaning procedures? You would be surprised how many EPC’s can’t answer this with a yes. Why does it matter? Can’t we just find a way to get in there and clean the system anyway? Closed systems with no access points at all are fairly common. [...]

Challenges to Combined-Cycle Plant Steam Blowing Procedures

Combined cycle plants using gas and steam turbines in parallel present a special set of challenges during cleaning. Any missed debris can cause millions of dollars of damage to the steam turbine if the procedure is performed incorrectly, and variances in pressure tolerance between a steam and gas turbine often mean steam blowing must be […]