Thank you for visiting our ExxonMobil Partner Page. Below are resources for your use. If you have any problems, questions or concerns, please call RIG at 800-770-4510

Services Brochure for Mobil Serv | RIG

This is a PDF you can email to potential customers that covers:

This is a PDF you can email to potential customers that covers:

- All plant reliability and pre-commissioning services offered by the Mobil Serv | RIG team

- Past project examples

- Key sales and project management team members

Service Overview Handout

A one-page handout you can provide to clients or potential clients that overviews our:

A one-page handout you can provide to clients or potential clients that overviews our:

- Plant reliability services

- Pre-Commissioning Services

- Embedded Technician Program

- and some recent project examples

Case Studies

We have a variety of case studies that cover previous project examples. Browse the selection of case studies here and download PDF’s you can email.

Whitepapers

From guides on removing varnish to preventative maintenance for lubrication systems, our whitepapers offer helpful tips and step-by-step guides that can be sent to customers and potential leads. You can view and download our whitepapers here.

Reliability Services Field Guide

This helpful PDF you can email to customers or prospects covers:

- What contaminates to worry about in industrial systems

- How to read ISO codes

- How to set cleanliness targets

- Choosing between sampling methods

- Fluid analysis methods

- Fluid power diagram symbols cheat sheet

- Helpful conversion charts

- and Additional Information

Oil & Gas Services Presentation

This PowerPoint walks through our services for oil & gas plants, including:

This PowerPoint walks through our services for oil & gas plants, including:

- Overview of our company and team

- Which services the plants should be performing and how often

- Details on specific service such as chemical cleaning, high velocity oil flushing, steam and air blows, surge flushing, hydro-testing, etc.

- Information on our equipment rental and engineering services

Gas Processing Plant Maintenance Guide

This two-page handout is for gas processing end clients. It explains

This two-page handout is for gas processing end clients. It explains

- Why maintenance is important in their facilities

- Which reliability services should be performed and how often

- Our embedded technician program for facilities that don’t want to manage the process

Embedded Technician Program Details

This PDF Download offers an overview of how we recruit, hire, train and deploy local plant technicians. It covers:

This PDF Download offers an overview of how we recruit, hire, train and deploy local plant technicians. It covers:

- What the program is

- Benefits of using our embedded technicians

- Details on the six step recruiting, hiring, training, deploying process

- How to contact us about the program

Scope Development Questions

This PDF Download offers a list of questions to gather a base scope for each of our plant reliability and pre-commissioning service jobs. Questions are separated by reliability or pre-commissioning first, then by service. For jobs with more than one service in the scope, use all applicable sections.

This PDF Download offers a list of questions to gather a base scope for each of our plant reliability and pre-commissioning service jobs. Questions are separated by reliability or pre-commissioning first, then by service. For jobs with more than one service in the scope, use all applicable sections.

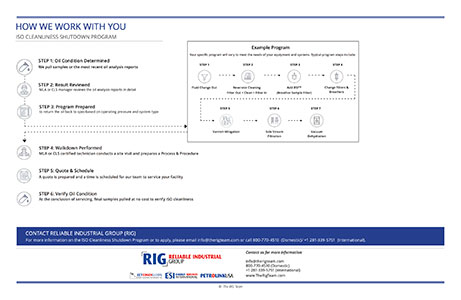

ISO Cleanliness Shutdown Program

This PDF download offers an overview and example of how we work with you based on the needs of your equipment and systems using a step-by-step program. Steps include:

This PDF download offers an overview and example of how we work with you based on the needs of your equipment and systems using a step-by-step program. Steps include:

Step 1: Oil Condition Determined

Step 2: Result Reviewed

Step 3: Program Prepared

Step 4: Walkdown Performed

Step 5: Quote & Schedule

Step 6: Verify Oil Condition

Best-in-Class Lubrication Program

This PDF download offers a detailed description for the 12 elements of the Best-in-Class Lubrication Program. Elements of a Best-in-Class Lubrication Program include:

This PDF download offers a detailed description for the 12 elements of the Best-in-Class Lubrication Program. Elements of a Best-in-Class Lubrication Program include:

- Safety/Environmental Practices

- Training Materials

- Program Management

- Program Tracking

- Lubrication Procedures

- Delivery / Storage Instructions

- Lubricant Dispensing Guidelines

- Equipment Contamination Control

- Lubrication Maintenance Practices

- Lubricant Selection Audit

- Monitoring Guidelines

- Sustainability / Adaptability Program

Contact one of the RIG sales representatives and experts below or call 800-770-4510

Larry Jordan, Sr. Technical Adviser

- 30+ years in industrial lubricants services

- Supports safety, commercial and operation activities for varnish mitigation and oil flushing

- Regular contributor to Machinery Lubricant Journal

Contact:

James Shannon, Engineering Manager

- 35+ years providing engineering design and executing pre-commissioning services worldwide

- Develops cleaning procedures, CAD drawings, material lists, and engineering calculations

- Leads training for all developing pre-commissioning engineers

Contact:

Lawrence (Scoop) Spriggs, Sr. Division Manager Pre-Commissioning

- 25+ years in industrial service pre-commission business (all service lines)

- Supports field personnel with technical and operational questions

- Internally organizes project execution and data collection

Contact:

Brian Cummings, Logistics & Procurement Manager

- 25+ years in procurement and mobilization in all facets of the pre-commissioning industry

- Supports project equipment requirements including fabrication, purchasing and shipping

- Helps develop accurate packages to reduce client costs

Contact:

- Email: [email protected]

Bruce Krol, Manager of Business Development and Pre-Commissioning

- 22+ years of experience in pre-commissioning and new construction power generation industries

- Leads project inception, design, sales and operations coordination, and implementation through final project acceptance and invoicing

- Ensures project schedules remain on track and maintains communication between EPC, plant owners, and technicians

Contact:

Ace Couture, C.E.T., Division Manager for Canada

- Graduate of NAIT’s Chemical Engineering Technology program as well as a Certified Engineering Technologist through ASET

- 12+ years of experience in the Chemical Cleaning and Plant Reliability Services Industry

- Degrees in both Chemical Engineering Technology (Northern Alberta Institute of Technology) and Environmental Studies (Cape Breton University)

Contact: