- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

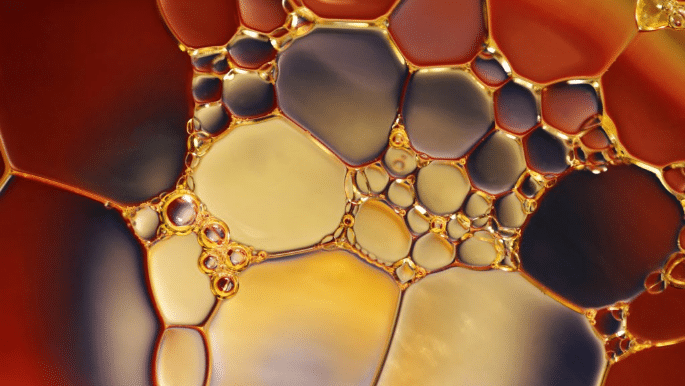

Is Your Hydraulic Fluid Getting Darker? Here’s What To Do

Hydraulic fluid is the lifeblood of your system, keeping everything lubricated and ensuring smooth machinery operation. It’s critical to regularly test your fluid to ensure contaminate levels are below ISO cleanliness levels and lubricant is circulating properly throughout your system. Unmonitored changes to your fluid could produce harmful effects that impact your system performance. But what do you do when your fluid is getting dark?

When Fluid is Too Dark

The first step is to have your fluid lab tested. Tests to uncover specific issues include:

- Fluid Analysis

- Acid Number (using FTIR)

- Viscosity (using FTIR)

- Oxidation (using FTIR)

Fluid Test Results Don’t Confirm Anything

If the fluid analysis comes back normal and the acid, viscosity and oxidation come back as stable, that indicates there’s no oxidation present in your hydraulic fluid. The next step is to inspect your valves. If there’s residue on the valves, there’s a possible indicator varnish is precipitating from the fluid.

What is Varnish?

Vanish is the byproduct of lubricant degradation and is generally unstable in oil. As such, it’s prone to form deposits or separate from your bulk oil. Varnish deposits can form on machine surfaces throughout your system, slowing down system performance, limiting valve function and shortening the life of your oil.

The primary cause of varnish is thermal degradation of some sort, which occurs in the absence of oxygen. Thermal degradation is caused by, you guessed it, heat! Typically, there are two broad causes of overheating in a hydraulic systems:

- A hot spot caused from an external heat source in close proximity to the lube system

- An implosion of entrained bubbles as the bubbles flow from the reservoir into higher pressure zones, such as pumps and valves

What to Do If You Confirm The Presence of Varnish

To solve the problem before it hurts your system performance, follow these steps.

- Confirm Thermal Degradation

Have a laboratory provide the FTIR curve of your oil. Don’t have them look at the wave-number region, where oxidation levels are measured. Instead, have them check for a peak in the nitration region. If a peak is present, then you’ve confirmed the presence of thermal degradation.

- Perform Root-Cause Analysis

Investigate the source of heat in your system. Once you know where the heat is coming from, you can determine whether there’s a major system flaw or if it’s possible to engineer a solution that will remove the heat source.

If your heat source is some sort of entrained air, there are engineered solutions to remove bubbles from the hydraulic fluid. If there’s a system design flaw, use a separation technology to remove thermal degradation byproducts from your fluid. This provides a long-term stop-gap solution to the varnish formation until you can implement a system redesign.

More About Reliable Industrial Group

At RIG, we’ve served more than 400 companies nationwide and can help you get to the bottom of system issues with a range of equipment assessments, including:

- Lubricant analysis

- Reservoir cleaning

- Lubricant reconditioning

- And auxiliary on-line filtration and flushing

We offer extensive varnish removal services and also carry a complete line of lubrication system accessories from filters, breathers and suction strainers to fill caps and site gauges.