What is often the most confusing about ISO codes is that the ISO number is a code that corresponds to a range, and is not a volume measurement itself. The

chart below shows how ISO codes correspond to volume measurements.

The important thing to remember is that for every 1 point increase in ISO code, there is a DOUBLING of the contaminate volume range. So, if you go from a code 19 to a code 20, you jump from a contaminate range of 2,500-5,000 particles per milliliter (p/ml) to a range of 5,000-10,000 p/ml.

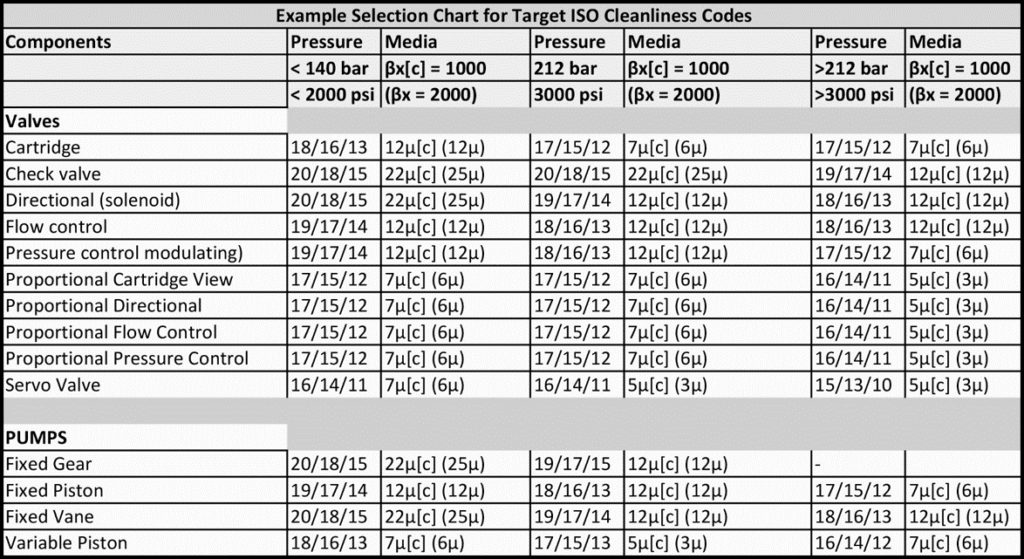

While every situation is different, we are often aiming for ISO code ranges that land somewhere between 12-17 for the first number, 10-14 on the second, and 8-13 for the third AFTER fluid reconditioning.

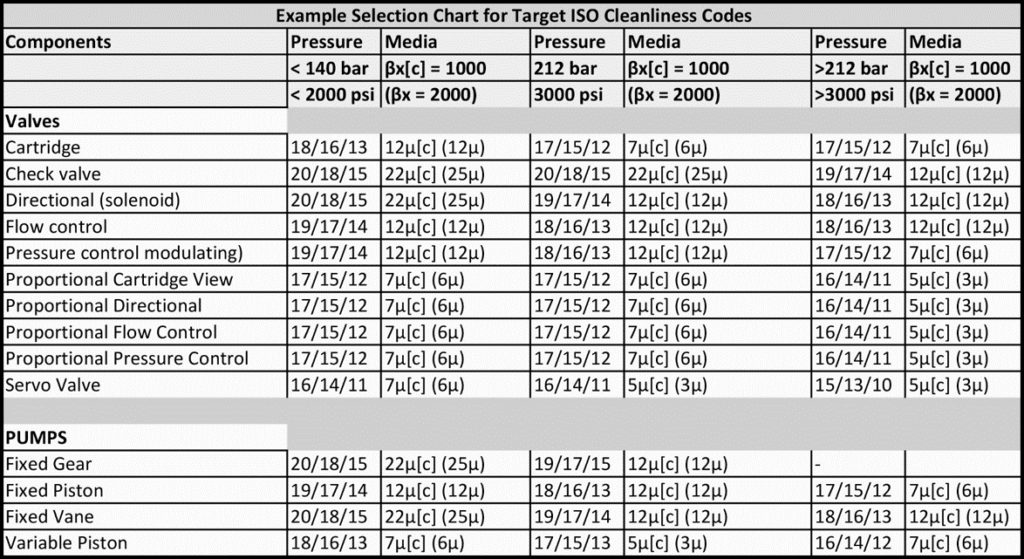

When we set goals for fluid reconditioning programs, we take several factors into consideration. Above is an example of a chart we might use to reference the following key factors and determine acceptable ISO codes and particle ranges. When using this chart, we are taking into account:

- Your main objectives for the cleaning program (minimizing repairs, extending equipment life, meeting regulations, satisfying warranties, etc)

- The most sensitive component coming into contact with the fluid, This component is the one we want to based the entire standard off of to make sure our fluid is optimized for that critical piece of equipment.

- The type of fluid used (petroleum or non-petroleum based fluids).

- The presence of additional factors, including:

- How critical the most sensitive component is to safety or overall system reliability

- Frequent cold starts

- Excessive shock or vibration

- Severe operating conditions

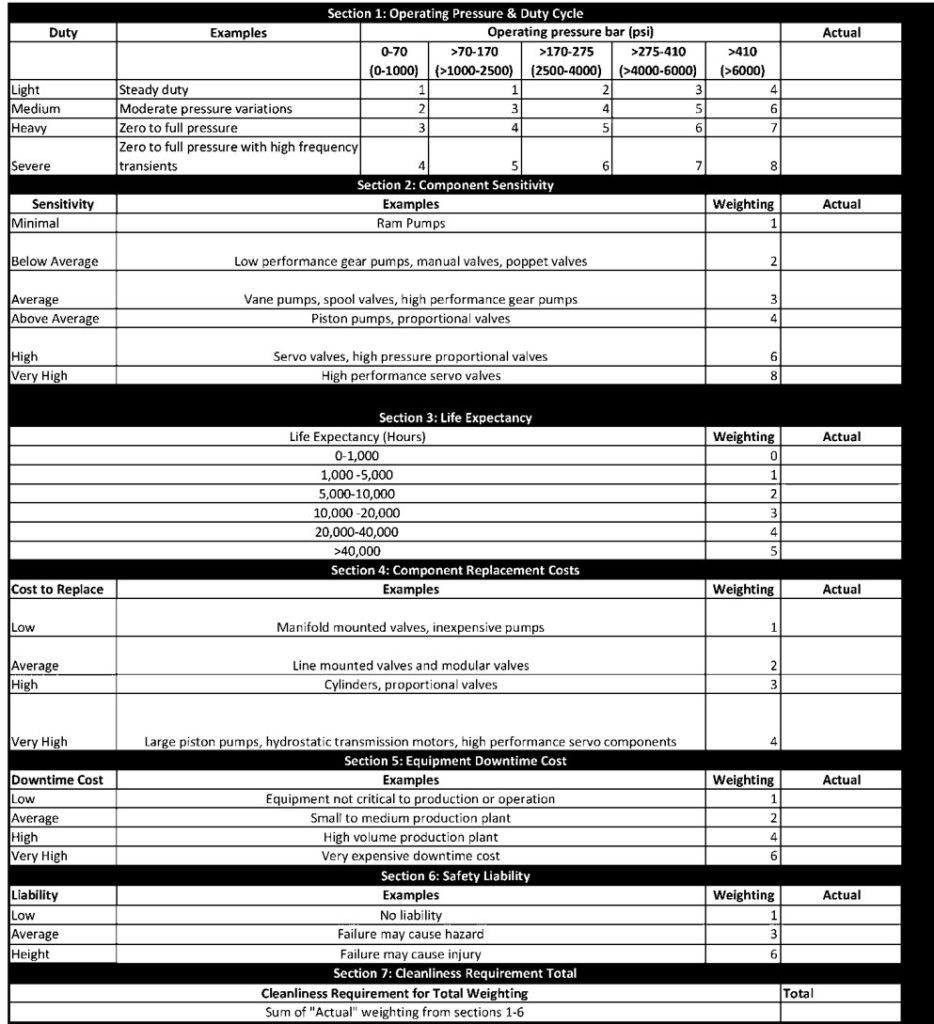

Use the list of parameters below to carefully consider operational and environmental conditions. Once complete, find your Recommended Cleanliness Level (RCL) by plotting weighted criteria on the chart on the next page.