- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

Optimizing Maintenance of Gas Processing Facilities

Regular maintenance and lubricant reconditioning of critical gas processing equipment can extend the life of your critical components, reduce oil replacement costs, and prevent the major causes of equipment failure.

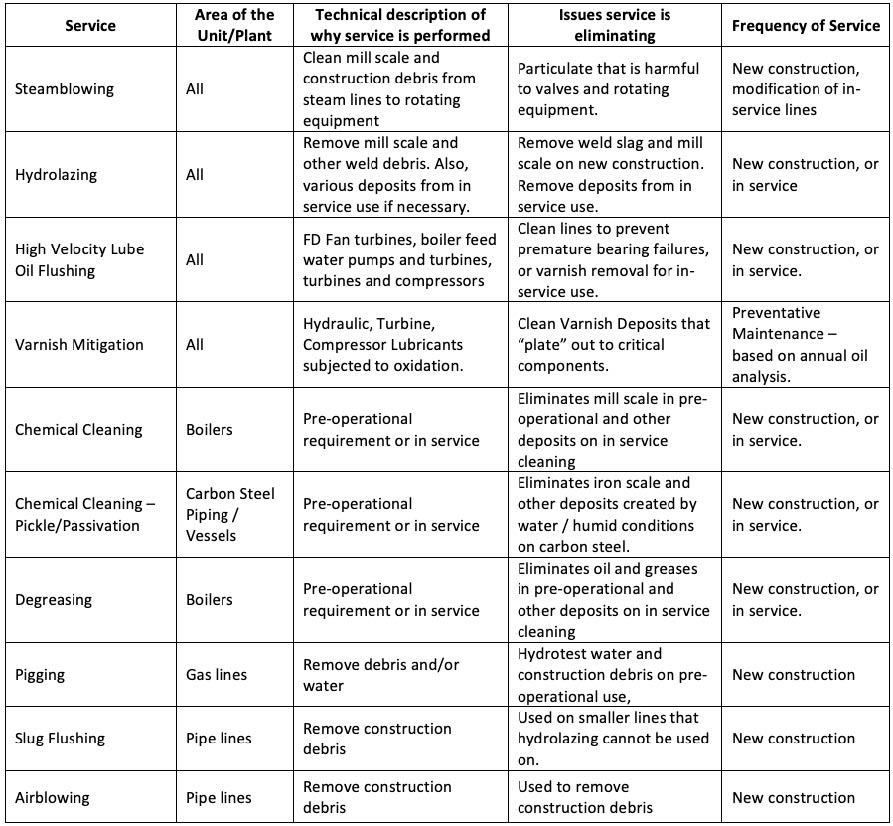

Which services should you be performing and how often? The chart below lays out an optimal maintenance schedule for Gas Processing Plants. Use this as a guide for setting up your maintenance program:

Table 1. Maintenance Schedule for Gas Processing Plants

EMBEDDED TECHNICIAN PROGRAM

If you don’t want to have to worry about tracking and upkeeping these reliability services yourself, the Reliable Industrial Group (RIG) philosophy is to embed a full-time technician to support your plant’s maintenance and reliability ambitions. Current Programs may include MLA or MLT trained personnel to perform services including:

- On site reclamation of hydraulic fluids

- Air breather supply and replacement

- Oil filter supply and replacement

- Oil sampling

- Oil sample report review

- Inline filtration, dehydration, and varnish mitigation

- Documentation, maintenance reporting, cost savings analysis

RIG’s embedded technician program is not limited to the above services. We can customize a number of reliability programs to meet the safety and reliability goals of your facility.

CONTACT RELIABLE INDUSTRIAL GROUP (RIG)

To work with the industry leader in plant reliability and maintenance services, call 800-770-4510 today or learn more at www.theRIGteam.com.