- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

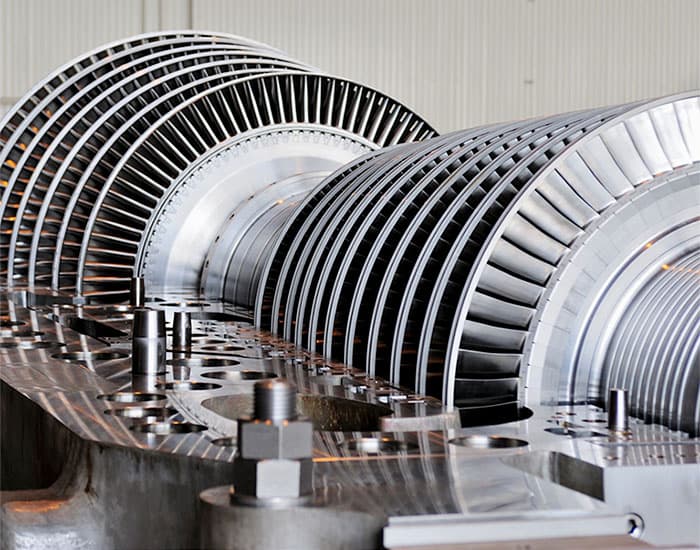

Turbine HPT5 Bearing

Project Summary

Provided services after a different flushing provider left a flange slip screen in place in front of turbine’s HP T5 Bearing.

Flushing procedures did not list the inspection point or verification of removal. The screen, plugged with contamination, starved the bearing of oil and caused $1.2M in damage and downtime.

To prevent unnecessary damage and lost time, it is recommended to use easy-to-identify PLI-Screens and include reinstatement steps in procedures.