- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

What filter do you need?

Generally speaking, there are 3 types of filters for solid and soft contamination. Each application is dependent on the efficiency and performance needed.

- Synthetic Microglass filters have smaller pore sizes with a higher efficiency ratio than most other filters.

- Synthetic media is less sensitive to moisture than cellulose or blown media and has a higher dirt holding capacity than other filters.

- Baldwin has a study that shows contamination that plugs 50% of cellulose filters will only plug 10% of synthetic media allowing for higher flow rates.

- Cellulose media is constructed of wood pulp and is a very economical means of filtration. We find that cellulose is less efficient than microglass but is very helpful when there is little water contamination in a reservoir that it would not be economical to run a fluid conditioner on.

- Melt Blown Filtration—Only used in fuel filtration applications and has very good water separation characteristics.

This does not mean that if you have water contamination, you must select a cellulose media. There are many vendors out there that will impregnate a microglass filter with water absorbing media in order to handle the task at hand. It is very important to pull data based on lubricant analysis in order to acquire the most economical filtration Cart for your applications.

Selection a Filter

Selecting the right filter and doing a proper setup is a specialty area of RIG’s. We can walk you through the process and ensure both critical equipment safety and minimal downtime during setup and breakdown. Some general considerations:

Selecting the right filter and doing a proper setup is a specialty area of RIG’s. We can walk you through the process and ensure both critical equipment safety and minimal downtime during setup and breakdown. Some general considerations:

- Fluid characteristics

- Lubricant Viscosity—High viscosity lubricants should not be pumped through fine filtration at high speeds due to air entrainment which results in cavitation and machine wear.

- Lubricant OEM—Some lubricant manufacturers have heavier additive packages than others. Lubricants with high defoamant additives should not be filtered with sub-micron filtration.

- Synthetic or Mineral Oil—Filter seal application is dependent on temperature, fluid type, and application.

- Type of Fluid—Initial determination of filtration media will be taken into account dependent on the amount of water in the lubricant or if it is a water/oil invert lubricant.

- Micron level rating — how fine a particle filters can catch

- ISO Standard 4406:1999, which covers hydraulic fluid contaminants, requires filtration of solid particles as small as four microns in the oil

- For context, a micron (μm) is one-thousandth of a millimeter — 0.00004. Traditional filtration can only remove particles to about 1 μm. And the smallest particle visible to the human eye is 25 μm; a human hair is about 100 μm wide.

- Rating: absolute vs. nominal

- Absolute — remove 98%+ of contaminants in one pass

- Nominal — remove 50% – 97% of contaminants in one pass (varies by manufacturer)

- Ability to withstand various process conditions — check manufacturer recommendations for the following to ensure proper filter operation:

- Temperature

- Pressure

- Flow rate

Example

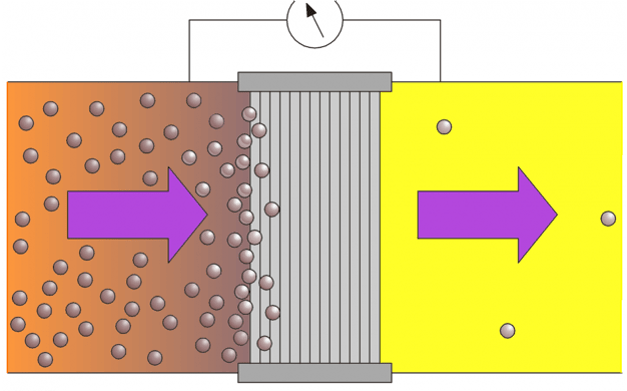

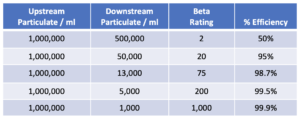

If a 10-micron filter has 1,000,000 particles upstream and 1,000 particles pass through its media, the Beta Ratio would be calculated as 1,000,000/1,000 – B1000. In addition, Beta Ratios can be expressed as an efficiency percentage-efficiency % – (Beta minus 1) / Beta * 100. The Beta 1000 element is 99.9% effective. See the efficiency chart below for more examples.