- Home

- About

- Services

- Air Blow Cleaning Services

- Oil Filtration Services

- Chemical Cleaning

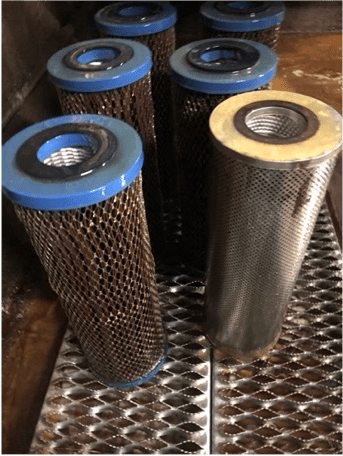

- Filters & Breathers

- Fluid Reconditioning Services

- Hydraulic System Decontamination

- Hydrolazing

- Hydrostatic Testing

- Oil Flushing

- MHC & EHC Flushing

- Reservoir and Tank Cleaning

- Steam Blowing

- Varnish Mitigation & Removal

- Additional Services

- Equipment Fleet

- Our Brands

- Projects

- Get A Quote

- Contact

Why You Can’t Skip Preventative Maintenance with Condition Based Monitering

How long has it been since you serviced your lube oil system?

With todays technology for oil analysis we have gone to a conditioned based response. Condition based is great for monitoring current condition of lubrication in the system but many times at the cost of preventative maintenance of the lube oil reservoir and filters. As a service provider it is not uncommon for us to hear that the reservoir has not been cleaned for 10 years and the filters are great…been running on the same filter for the last 3 years.

With todays technology for oil analysis we have gone to a conditioned based response. Condition based is great for monitoring current condition of lubrication in the system but many times at the cost of preventative maintenance of the lube oil reservoir and filters. As a service provider it is not uncommon for us to hear that the reservoir has not been cleaned for 10 years and the filters are great…been running on the same filter for the last 3 years.

Meanwhile, contaminates, varnish and water are dropping out and building up in your reservoirs and system low-points. Condition based monitoring does not provide accurate measurement of these dangers threats to your critical parts and system internals, especially because when they congregate in reservoirs ISO counts in flowing fluid may appear to be low. That is, until the day they are suddenly sky high!

Even with a condition based program, filtration and reservoir cleaning should be on your preventative maintenance list to extend the life of the increasingly costly hydraulic fluids and protect the life of your equipment.

RIG can help you with a custom built embedded lubrication program.

From oil analysis, contamination control, oil reclamation, breathers and filters RIG is here to help.

Contact the Reliable Industrial Group team at 1-800-770-4510 for more information or email [email protected]